Packaging and testing factory expands overseas production, Star/Malaysian/Richeng is the first choice

The U.S.-China trade war and the COVID-19 epidemic have erupted in recent years, which have subverted global supply chain thinking. Amid geopolitical considerations, many international companies have requested "Taiwan +1". Therefore, how to allocate production capacity efficiently and flexibly has become an important issue for manufacturers. subject. Currently, many packaging and testing factories are in the process of overseas expansion or have evaluation plans, with Malaysia, Singapore, and Japan as their first choices. The outside world is paying close attention to whether more supply chains such as related consumables and equipment will follow suit to expand overseas layout.

Southeast Asia has gradually become an important global semiconductor cluster in recent years, with major global IC design companies and IDM factories already stationed there. According to the "Taiwan Electronic Equipment Industry White Paper", the growth rate of Taiwan's semiconductor equipment exported to Singapore and Malaysia has increased significantly in recent years. This is due to the development of the local packaging and testing industry and the increased investment of major international manufacturers. This is why the two places have become Taiwan's packaging and testing factories in Southeast Asia. The reason why the layout is preferred.

ASE Investment Holdings, a leader in packaging and testing, believes that geopolitical risks are not the main reason for expansion, but local customer demand and costs are more important. The company has continued strategic capital investment in Malaysia for decades. Its new packaging and testing factory in Penang, Malaysia is expected to be completed in 2025. The core products of the factory are copper clips and image sensors that are in large demand. Packaged products.

WinWay, a major semiconductor test interface manufacturer, also regards Malaysia as a key market. Since setting up a business and technical service center (WinWay Penang Service Center) in Penang, Malaysia in May last year, the regional management team has become more complete and the relationship with local customers has deepened. , the company is also evaluating the feasibility of setting up a factory locally.

Chen Shaokun, senior vice president of Yingwei Global Business and Operations Center, said that the upstream and downstream semiconductor industry chain in Malaysia is becoming more and more complete. In addition to the continuous expansion of the original large-scale OSAT factories and IDM factories, important IC design companies around the world have successively settled in. The company has a strong focus on Southeast Asia. Confidence in market control and business expansion.

Xinquan already has a production base in Singapore. The second new factory is targeted at advanced semiconductor testing projects such as HPC, 5G and automotive. The factory, together with the initial factory buildings and production lines, is expected to invest US$250 million within 6 years. and expand Singapore’s advanced testing capabilities. The plant is approximately twice the size of the existing plant and is expected to be completed and put into production in 2024.

Compared with other peers who prefer Southeast Asia to expand production, semiconductor packaging and testing factory Licheng has observed the successful case of TSMC's investment in Kumamoto, Japan. The company is also evaluating the construction of advanced packaging plants in Japan, and is based on the premise of a joint venture, but it has not yet reached an agreement with Customers negotiate; if the plan does not materialize, Southeast Asia will be considered.

Industry insiders analyze that the fixed costs of the packaging and testing industry are relatively high, and equipment utilization will directly affect the company's profit performance. In addition, the bargaining power of packaging and testing factories is not as high as that of wafer factories. In the past, they often got the bargaining share. Without sufficient long-term demand and government subsidy support, it is not appropriate to set up factories overseas. Furthermore, the product lines and customer base of some packaging and testing plants are quite dispersed, and it may be difficult to support the demand for plant construction with only a single customer. These are the reasons why relevant manufacturers have a cautious investment attitude.

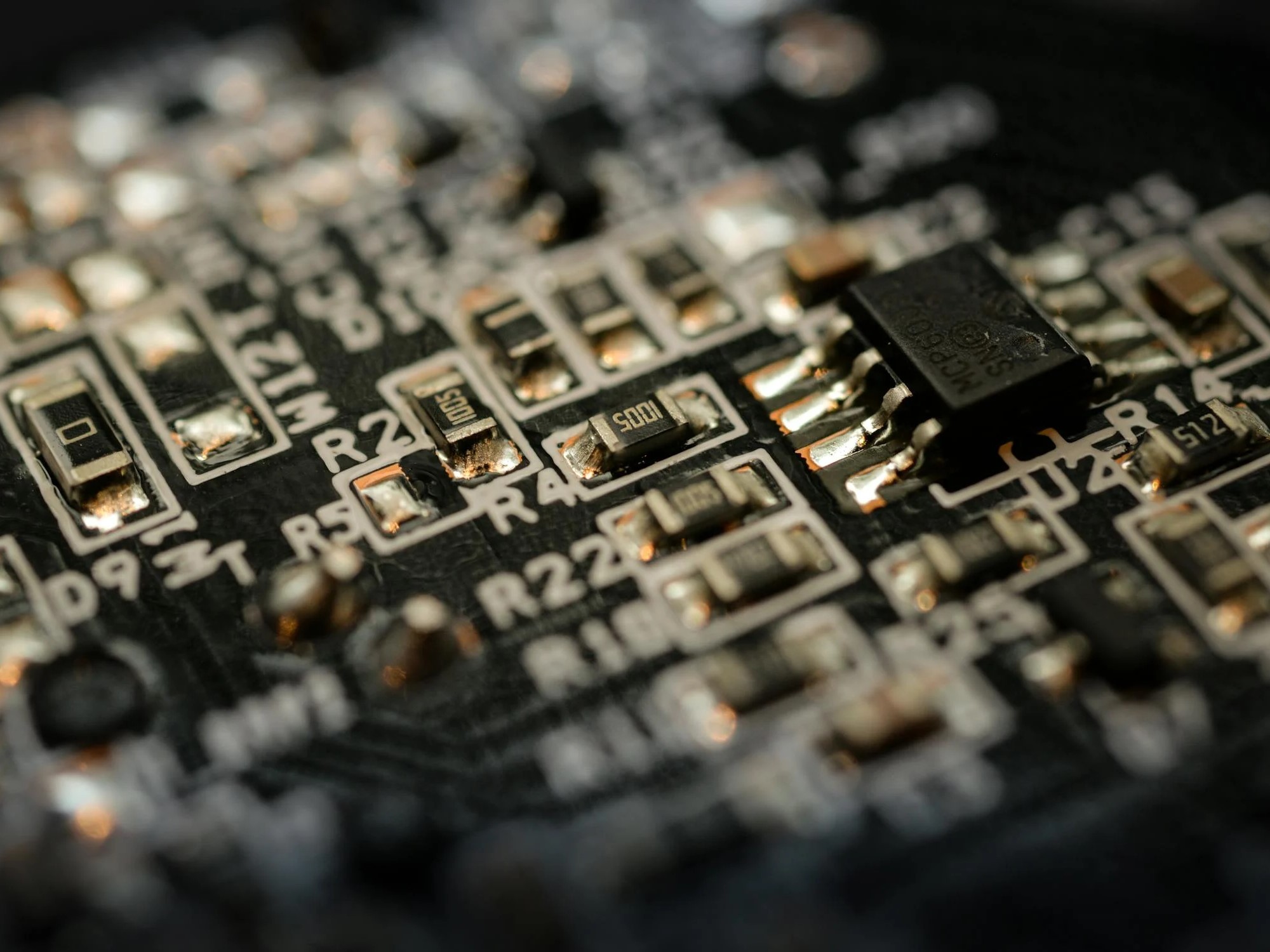

(This article is reprinted with permission from MoneyDJ News; first image source: Image by Freepik)

Related links:封測廠海外擴產,星/馬/日成首選 | TechNews 科技新報

【Disclaimer】

The content of this article only represents the author's personal views and has nothing to do with Kuiding.

The content, textual description and originality have not been confirmed by this website. This website does not make any guarantee or commitment for this article and all or part of its content, authenticity, completeness and timeliness. It is for readers' reference only. Please verify the relevant content by yourself.

馗鼎奈米科技股份有限公司 Creating Nano Technologies,Inc.

59 Alley 21 Lane 279, Chung Cheng Road, Yung Kang City, Tainan, TAIWAN

TEL: 886-6-2323927 FAX:886-6-2013306 URL: http://www.creating-nanotech.com