Panel-level packaging is emerging, and Taiwanese manufacturers are building a one-stop supply chain

TechNewsTechnology News

September 21, 2024

Author Central News Agency Zhong Rongfeng

September 21, 2024

Author Central News Agency Zhong Rongfeng

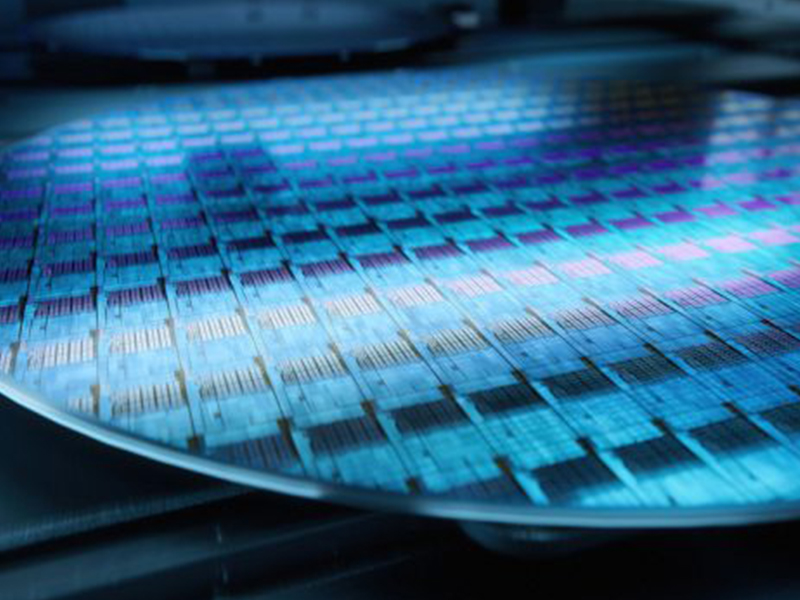

Artificial intelligence (AI) chips have driven advanced packaging to be in short supply, and the development of panel-level fan-out packaging (FOPLP) has become the focus of market attention. Taiwanese factories including Innolux, Power Technologies, ASE Investment Controls, and TSMC are planning for mass production. Semiconductor equipment manufacturers are also actively blocking positions and striving for a one-stop supply chain.

The Industrial Science and Technology International Strategic Development Institute of the Industrial Technology Research Institute pointed out that square panels with panel-level packaging can accommodate more packaging units than circular wafers. Increased use area can increase production; improved electrical and heat dissipation performance can improve packaged component performance. In addition, the etching and plating process costs can be reduced, reducing material consumption.

Taiwan's semiconductor manufacturers include TSMC (2330), ASE, PowerCenter (6239), Innolux (3481), Silicon Products, etc., and are actively deploying panel-level fan-out packaging; in addition, Samsung Electro-Mechanics (SEMCO), a subsidiary of South Korea's Samsung Electronics, and Ike Amkor, Nepes, etc. have also been investing in panel-level packaging technology for a long time.

From a client perspective, market analysts analyze that NXP, STMicroelectronics, AMD, Qualcomm, etc. are cooperating with Taiwanese manufacturers to adopt panel-level packaging.

Wu Tianyu, chief operating officer of ASE Investment Holdings (3711), estimates that panel-level packaging equipment will be in place as soon as the second quarter of 2025. Hong Songjing, senior deputy general manager of ASE, said that ASE has been deploying panel-level packaging for several years, and its wafer warpage control has met the specifications of process automation equipment, and the yield rate has also been greatly improved.

Innolux's panel-level packaging will begin mass production this year, and the monthly production capacity can reach 15,000 pieces in the future; Licheng began to set up a panel-level packaging production line in 2016, began mass production in 2019, and expanded the panel-level packaging production line in 2021.

On the equipment side, Taiwanese manufacturers are actively entering into panel-level packaging production line equipment. Tisheng (8027) cooperates with panel and packaging and testing companies, and uses panel companies to enter European power management chip manufacturers. Local securities firms predict that Titanium will gain new U.S. customers in 2025 and will have the opportunity to expand production next year.

Manz Technology has developed an advanced panel-level packaging architecture based on glass substrates. The redistribution layer (RDL) process equipment has been applied in panel-level packaging. It has shipped nearly 10 RDL production lines to 5 major domestic and foreign customers.

A local legal person pointed out that Deng (3680), a semiconductor advanced carrier equipment merchant, has also deployed panel-level packaging transfer boxes based on glass substrates. The new transfer box products are expected to be mass-produced in 2025. In addition, automatic optical AOI testing equipment manufacturer Jingcaike (3535) has launched a panel-level packaging die position measurement machine to enter packaging and testing plants. Jingcaike has also launched RDL-related AOI testing equipment.

Quantum Technology (3167) has also cooperated with packaging and testing factories to launch die bonding testing equipment; Uveko (3580) has also deployed panel-level packaging related equipment.

According to analysis by equipment industry players, including Innolux, Power Technologies, ASE Investment and Control, etc., they already have the conditions for mass production of panel-level packaging. Most panel-level packaging is used in power management chips for mobile phones, cars, and wearable devices. In addition, low-orbit satellite radio frequency (RF) chips will also use panel-level packaging.

As for when artificial intelligence AI chips will be introduced into panel-level packaging, equipment industry players said that there are certain technical limitations on line width and line spacing, and the progress of panel-level packaging in the commercialization of high-end AI chips remains to be seen.

According to an analysis by the Industrial Science and Technology International Strategy Development Institute of the Industrial Technology Research Institute, Taiwanese companies have entered the panel-level packaging market and expanded business opportunities through the transformation of old panel factories or carrier board factories and the extension of semiconductor technology. However, panel-level packaging still has material interfaces in technology. Issues such as thermal expansion coefficient mismatch, large-format wafer warpage and displacement, and carrier plate uniformity need to be overcome.

【Disclaimer】

The content of this article only represents the author’s personal views and has nothing to do with Creating.

The content, textual description and originality have not been confirmed by this site. This site does not make any guarantee or commitment for this article and all or part of its content, authenticity, completeness, and timeliness. It is for readers' reference only. Please verify the relevant content by yourself.

Creating Nano Technologies, Inc.

59 Alley 21 Lane 279, Chung Cheng Road, Yung Kang City, Tainan, TAIWAN

TEL:886-6-2323927 FAX:886-6-2013306 URL: http://www.creating-nanotech.com